Addressed Challenges

The research project is addressing three main challenges for develop construction robots and are summarized below:

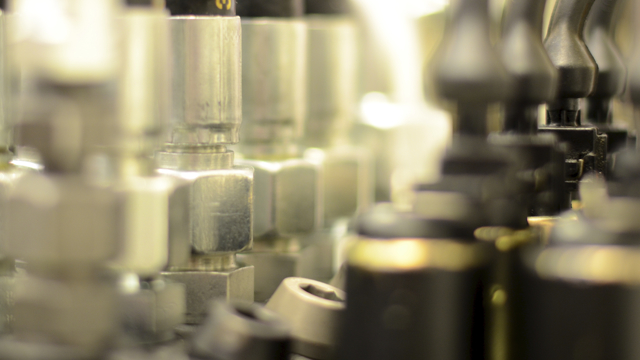

- Reducing the time to market of new machine concepts with improved energy efficiency is a critical aspect to reach the climate change goals. One target in this project is to improve the quality in concept evaluation, reducing the risk of stalling the development to reach the market quicker. The design process and suggested methodology addresses the increased complexity when considering the machine main sub-systems; propulsion and work implement actuation, where actuation is based on hydraulic drives.

- Improving energy efficiency is essential for the future of construction machinery. This research project aims at reducing energy losses in the motion systems by improved control principles, allowing concepts to operate closer to their theoretical optimum, more importantly when in real-time operation. To achieve the best possible complete machine efficiency the controls of both propulsion and actuation systems must be coordinated, which is today a significant challenge due to their strong interaction during machine operation, especially in wheel loaders.

- Automation is important for future machines. Increased productivity, increased safety and reduced energy consumption are positive outcomes of automation. In autonomous machines operation can be carried out based on pre-information of an assigned work task and machine data at hand. A sophisticated control system can make real-time control decisions with big impact on the total energy consumption. The expected result from this topic in the project will be a reduced electric energy consumption. This will lead to a better utilization of installed battery capacity allowing for improved operating range and/or usage of smaller batteries, reducing the environmental footprint.