Research focus is mainly on metallic materials but also ceramics, composites and polymers for engineering applications. This includes high temperature materials such as Ni-based superalloys and coatings for gasturbines, advanced austenitic stainless steels for the power plants, cast iron for heavy vehicle engines and aluminium and titanium alloys for the aircraft industry.

Materials have always played an important role in our lives. We are surrounded by materials and without curiosity and desire to uncover the structure, properties, performance, manufacturing process and applications of these materials there would not be innovations like jet engines, wind turbines or 3D-printed airplane components.

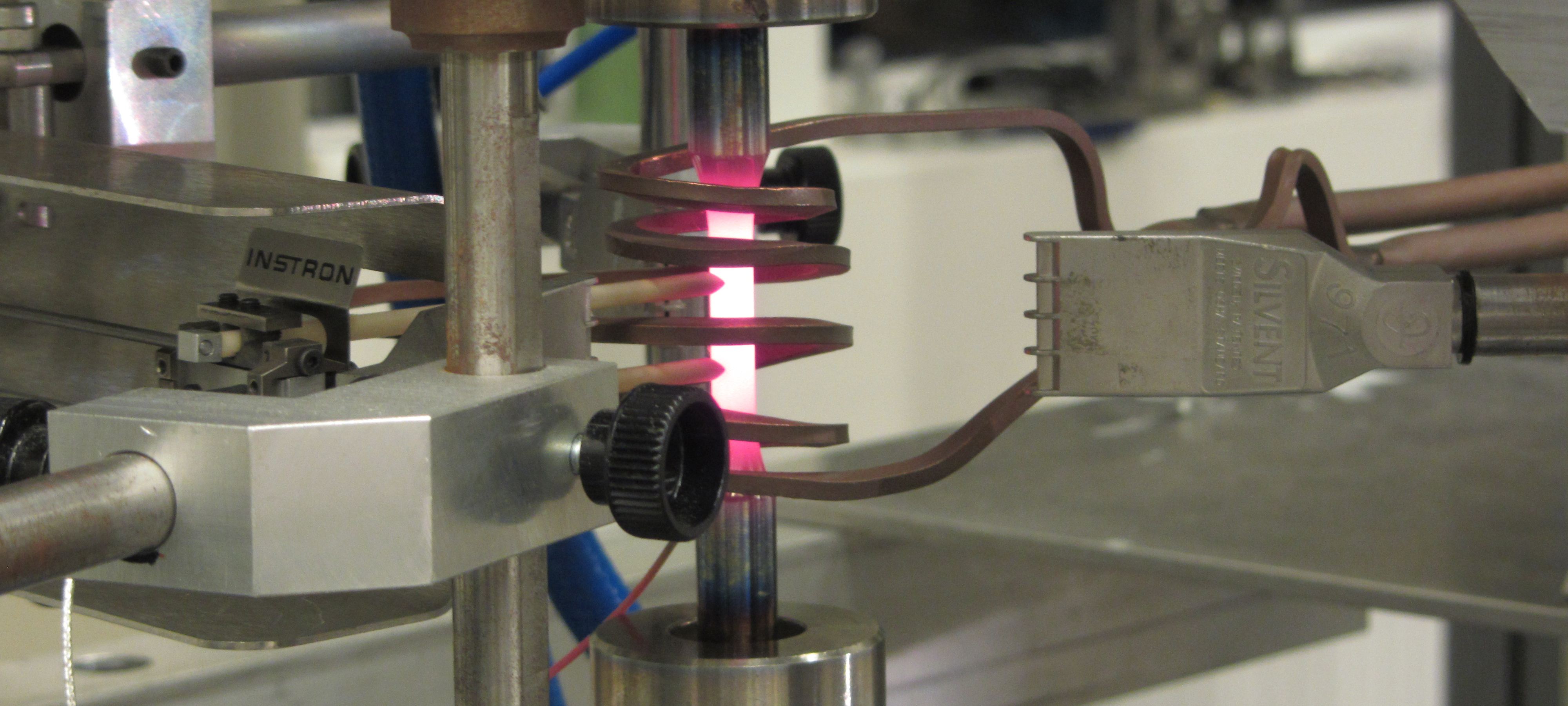

We study the relationship between microstructure and mechanical properties, environmental impact and degradation of material properties, and fatigue and durability of material under service like conditions.

We aim to promote the optimal use of traditional materials but also to be the bridge between the synthesis of new materials and their use in engineering applications. We are the link between the experimental characterisation of materials and the mathematical description of their behaviours in order to support more efficient product development and manufacturing processes.