My colleagues and I help to increase the knowledge in the field of Production Economics. We offer several courses in Operations Management at the graduate and undergraduate level to spread basic knowledge and the latest research in the subject. Focusing on digitalization in manufacturing companies and on initiatives such as Industry 4.0, the manufacturing systems will definitely be different in the future. It is really exciting to be involved in designing these systems.

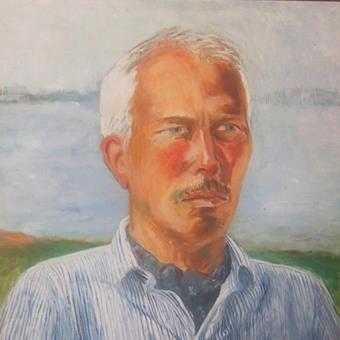

Fredrik Persson

Senior Associate Professor, Head of Division

My subject area is Production Economics where I specialize in modelling and simulation. I teach advanced courses and research different topics in Operations Management.

Production Economic Research with Focus on Finance and Operations Management

The interest in digitalization is increasing all around us. While digitalization allows for new opportunities for communication between individuals, the same is true between and within manufacturing enterprises. What kinds of manufacturing systems will we see in the future and how are they going to analyzed, planned and controlled?

Production Economics is a subject area where the engineer's tools are used of on economic problems. The topic concerns the management of production factors and is aimed at the manufacturing company's financing, planning and control. The goal is to increase the manufacturing company's financial and production-related competitiveness.

My colleagues and I help to increase the knowledge in the field of Production Economics. We offer several courses in Operations Management at the graduate and undergraduate level to spread basic knowledge and the latest research in the subject. Focusing on digitalization in manufacturing companies and on initiatives such as Industry 4.0, the manufacturing systems will definitely be different in the future. It is really exciting to be involved in designing these systems.

My colleagues and I help to increase the knowledge in the field of Production Economics. We offer several courses in Operations Management at the graduate and undergraduate level to spread basic knowledge and the latest research in the subject. Focusing on digitalization in manufacturing companies and on initiatives such as Industry 4.0, the manufacturing systems will definitely be different in the future. It is really exciting to be involved in designing these systems.

More about my research

Finding solutions to modelling problems

An area that interests me is discrete event simulation (DES). I have studied several applications from large logistics system, where I worked with the SCOR-model as the basis for simulation, to smaller systems within health care, correctional care, manufacturing, and warehouse operations.

The research is mainly about finding new solutions on modelling issues and new ways to analyze the output data, find causal relationships and to carry out screening and experimental design.

The research is mainly about finding new solutions on modelling issues and new ways to analyze the output data, find causal relationships and to carry out screening and experimental design.

Lean System

In my research in production planning and control, I examine all the different planning systems. Lean production is perhaps the system that has increased in interest the most in recent years.

Many companies don not use Lean to their full potential and therefore run the risk of undermining their own activities and personnel. In the field of Human Lean we study the personnel and how the system works on an individual level.

Many companies don not use Lean to their full potential and therefore run the risk of undermining their own activities and personnel. In the field of Human Lean we study the personnel and how the system works on an individual level.

Publications

2023

Continue to DOI

Continue to DOI

2017

Continue to DOI

Continue to DOI

2015

Continue to DOI

Continue to DOI

2014

Continue to DOI

Continue to DOI