Research in product development at LiU is conducted in close collaboration with industrial partners. In common for the various research areas is that the need for new methods and tools increases as both the products and the product development process are becoming increasingly complex.

Ever-increasing numbers of products include both hardware and software, mechanical components, electronic circuits and possibly also hydraulic or pneumatic components. Requirements on materials expertise, customer adaptation and short product lifecycles are also increasing.

Model-based and automated design is a focus area in which LiU leads the field. In such research, a designer constructs modules of various parts of a product in the computer. These modules can subsequently be changed and modified individually and combined to give several new products, adapted for, for example, distinct categories of customer. The designer defines the needs of the user and carries out the creative aspects of the work, while the computer suggests several designs based on limitations specified by the designer. The model is simulated and subsequently optimised in the computer before a prototype can be produced.

Additive manufacture, also known as “3D printing” is used not only to build prototypes but also for research into resource-efficient product development and to develop methods for design for additive manufacturing.

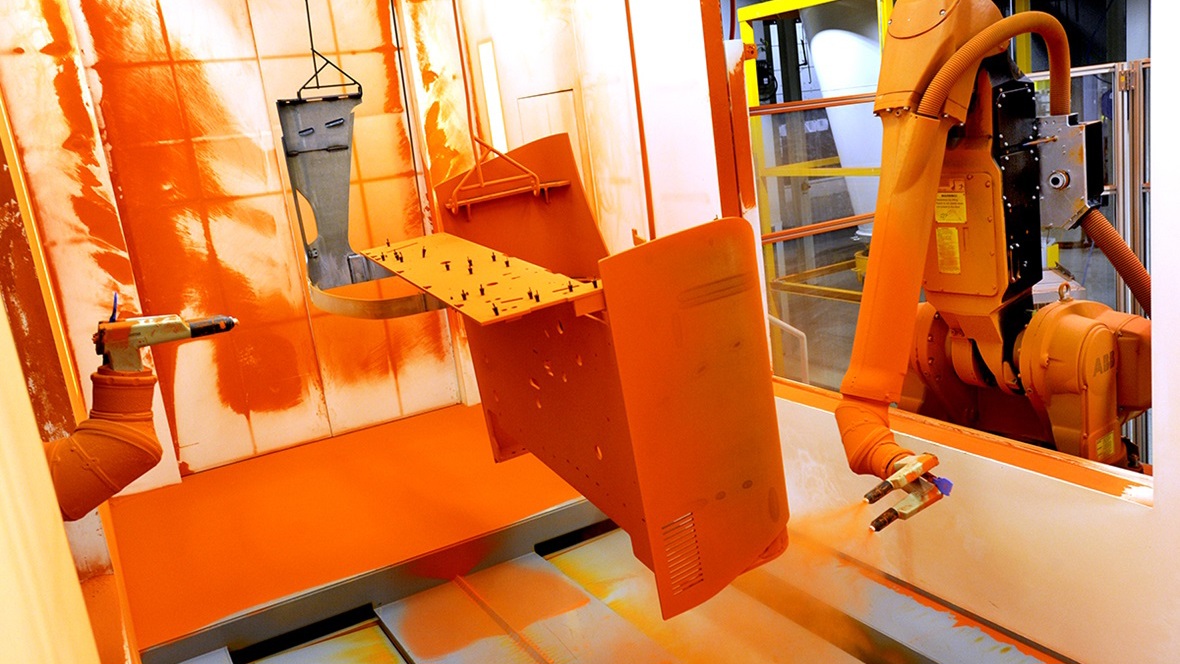

Research into product development for sustainability, resource-efficiency and manufacturability is another focus area in which LiU excels. The goal is to develop products that minimise the consumption of resources during their complete lifetime, consume as little energy as possible, or that can be reused, remanufactured or, as a last resort, recycled. It must be possible to design, manufacture, use and possibly also recycle a product in such a resource-efficient manner as possible during its complete lifetime. The optimal solution depends on the particular product, and it is in the early phases of product development that the greatest steps towards increased resource-efficiency can be made.

LiU also coordinates the research programme Mistra REES - Resource Efficient and Effective Solutions.

Industrial design is a closely related research area.